Design

CAD Room

The CAD Room uses CAD software to create data describing the shapes of the parts customers require. Personnel use NX, CATIA Ver. 5, and SOLID-WORKS. The suitability of shapes created with CAD software is analyzed using CAE software as part of an advance verification process. This process includes nonlinear structure analysis using MARC/ABAQUAS, acoustic analysis using ACTRAN, and fluid analysis using STAR-CCM.

Materials

Material Testing Lab

The Material Testing Lab offers comprehensive testing capabilities for all rubber and resin products. Personnel study rubber formulations using a test kneader and rolling machine. They use a Mooney viscosity meter and curelastometer to test rubber’s vulcanization characteristics. A two-axis resin extruder is used to test resin formulations. Personnel also use a fluidity tester to measure MFR. Other equipment includes a Sunshine Weather Meter, xenon and ozone testing equipment, and a temperature and humidity testing chamber, which are used in environmental testing.

Products

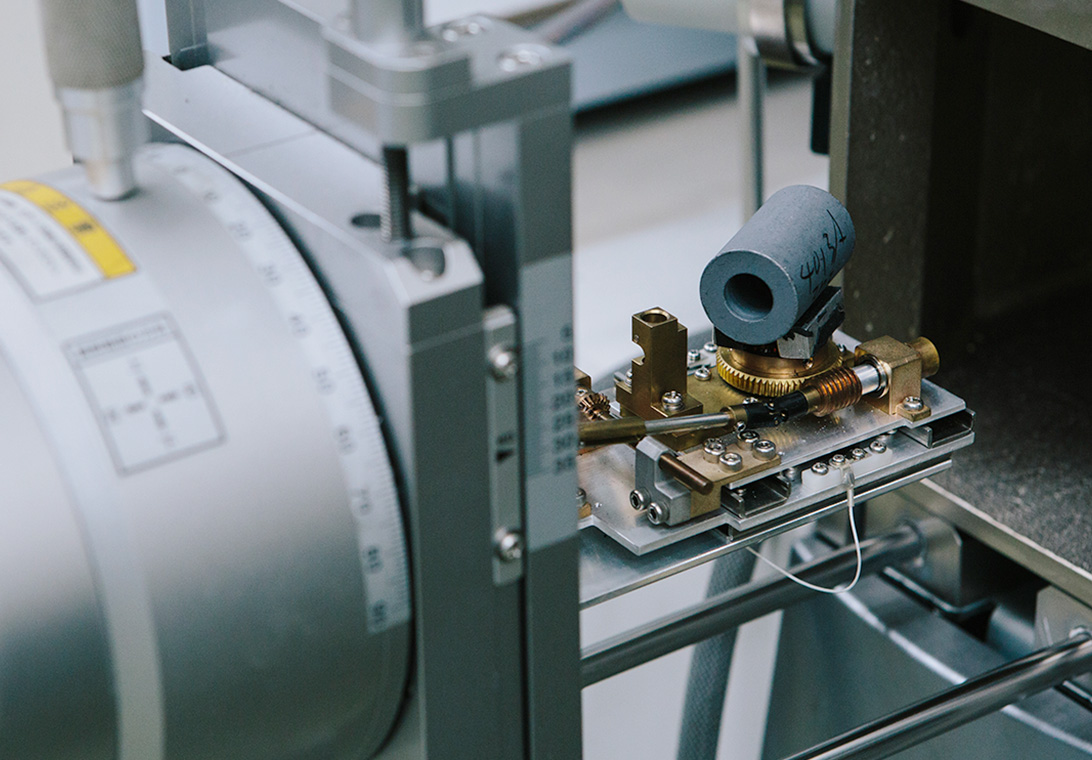

Composite environment and vibration tester

This tester is used to evaluate the strength reliability of fresh-air ducts and resonance chambers by subjecting them to vibrations. By subjecting tested parts to vibrations based on preconditioned temperature and humidity settings, it carries out environmental evaluation testing under compound conditions.

Multi-axis durability tester

This tester carries out both single- and multi-axis tests of static and dynamic spring characteristics, reliability, noise, and other characteristics for suspension bushings, stabilizer bushings, strut mounts, and other parts. It can conduct performance and reliability tests based on compound inputs designed to imitate an actual vehicle. It can also carry out tests under temperatures ranging from low to high.

Testing and measurement

Scanning electron microscope (SEM)

This microscope detects secondary electrons generated, and electrons reflected, by the surface of samples. It is used to test adhesive vibration-damping bushings with metal fixtures such as strut mounts and trailing bushings. We apply a zinc phosphate coating to metal hardware in order to improve the reliability and durability of cure adhesion. The SEM is used to evaluate whether that zinc phosphate coating has formed properly.

Hemi-anechoic Room

This facility is designed to block sound from external sources and to limit sound reflections and interference in the room. It is used to test parts such as undercovers and dashboard grommets. Sound-blocking performance can be evaluated by placing a vehicle in the room and measuring the amount of sound inside and outside the room when noise is generated outside the vehicle to determine the amount of sound that enters the vehicle. The sound-blocking performance of individual products and at specific vehicle locations can also be measured.

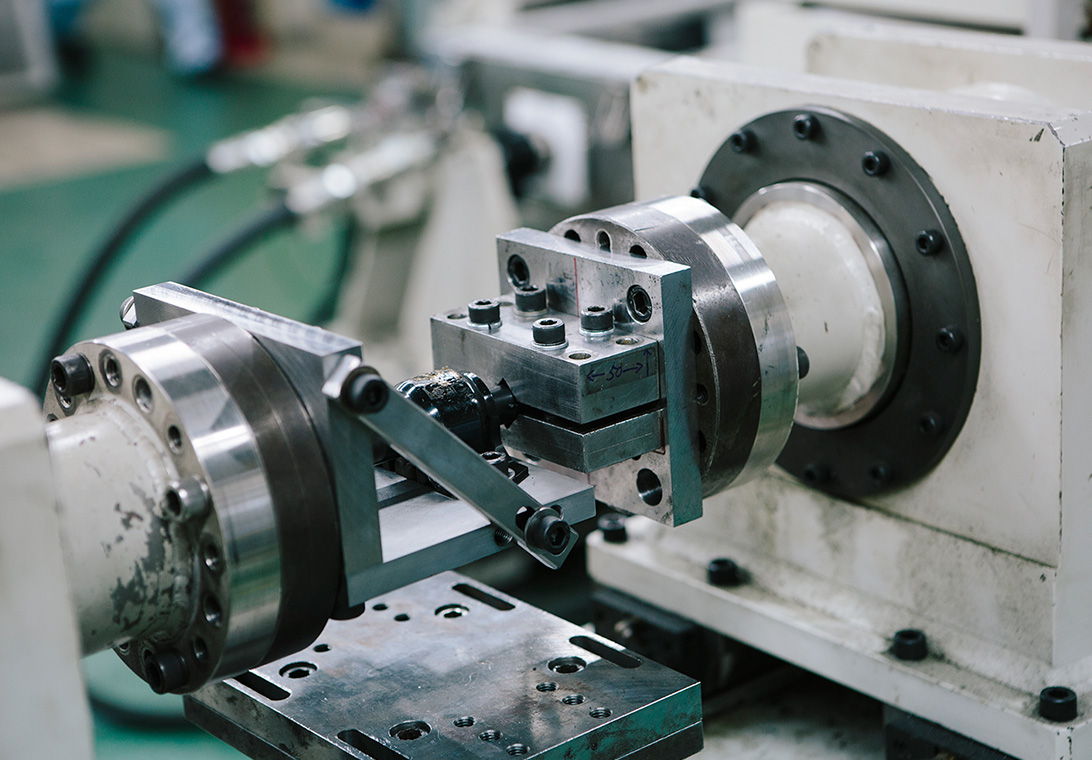

Three-dimensional measuring instrument

This instrument can make three-dimensional measurements and coordinate measurements of all rubber and resin products. It can also make measurements automatically based on a program, allowing the same part to be measured multiple times in an extremely precise and efficient manner.

Track Day

The Track Day initiative allows people to actually drive cars, so that they can experience vehicles not just as a means of transportation but also as a source of pleasure. This gives them a unique understanding of the importance of the automotive parts that make that pleasure possible. Sometimes we take advantage of Track Day events to install developed by Molten so that their benefits can be evaluated in a quantitative and qualitative manner.